Trilogy Metals Announces Potential for By-product Germanium at the Bornite Copper-Cobalt Project, Alaska

September 7, 2023

September 7, 2023 – Vancouver, British Columbia – Trilogy Metals Inc. (TSX/NYSE American: TMQ) ("Trilogy" or the "Company") is pleased to announce recent research conducted with the assistance of the Colorado School of Mines (the “School”) and the United States Geological Survey (“USGS”) has highlighted the potential for germanium to be a by-product during future copper production from the South Reef area of the Bornite copper-cobalt project. Germanium is a critical element with increasing demand in modern technologies and significant supply risks. China, the world’s largest producer of germanium, has adopted export controls intended to restrict the export of germanium, among other metals.

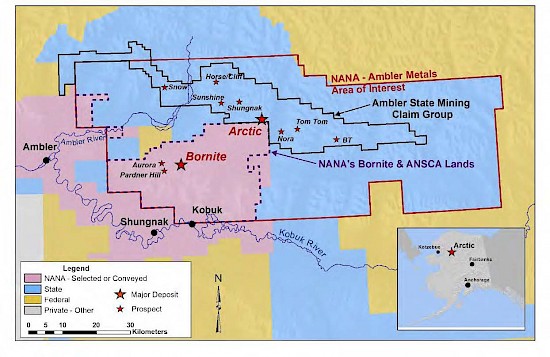

Additionally, Ambler Metals LLC ("Ambler Metals"), the joint venture operating company owned equally by Trilogy and South32 Limited (ASX, LSE, JSE: S32; ADR: SOUHY) ("South32"), will be providing samples to the School and the USGS to be used in their collaboration on critical minerals in the US. The Bornite project is part of Ambler Metals’ Upper Kobuk Mineral Projects ("UKMP") in northwestern Alaska which also includes the flagship Arctic copper-zinc-lead-silver-gold project, and surrounding state mining claims and NANA Regional Corporation, Inc. (“NANA”) lands.

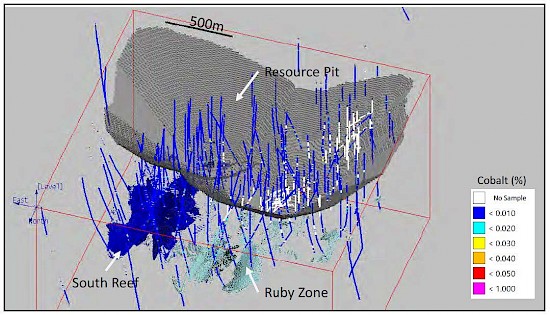

Bornite is located approximately 24 km southwest of the Arctic deposit that is envisioned to be served by the Ambler Access Road (see Figure 1). The Bornite deposit has a total Inferred resource of 6.5 billion pounds of copper (see Table 1). It is a carbonate-hosted copper deposit with stacked stratabound mineralized bodies or ‘reefs’ (see Figure 2) that include the near surface Lower and Upper Reefs, that together have an In-Pit Inferred resource of 170 million tonnes (“Mt”) grading 1.14% copper (using a 0.5% copper cut-off) and the deeper and higher-grade Ruby Zone and South Reef area. South Reef has an Inferred resource of 22 Mt at 3.48% copper (using a 1.79% copper cut-off).

Germanium at South Reef

Germanium values ranging from <1 to 125 ppm were measured in 84 core samples taken from five drill holes from South Reef as part of a recently completed Master of Science thesis done at the School. The samples, averaging 15 cm in length, were selected to establish the presence of germanium sulphides at South Reef. Due to the known association between copper sulphides and germanium seen by the USGS in the 1980s, higher copper grades (>5% copper) in the South Reef core were a key criteria in the sampling strategy. Although the samples represent only a small part of the South Reef area, the results clearly demonstrate that germanium is present at levels that are significantly higher than values obtained using a standard analytical method where a volatile germanium compound is lost during reaction with hydrochloric acid.

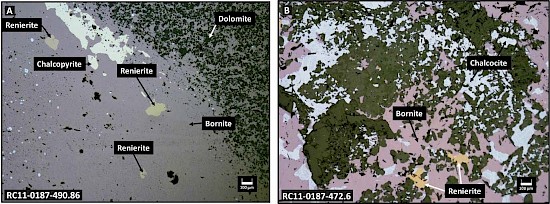

Importantly, the thesis work confirms the close association between the germanium sulphide renierite (Cu10ZnGe2Fe4S16 to Cu11GeAsFe4S16) and copper sulphides, most commonly bornite and chalcocite (see Figure 3). In the 1980s, the USGS identified renierite and germanite (Cu13Ge2Fe2S16) in samples from the Ruby Zone occurring as discrete grains up to 75 microns across, embedded within grains of bornite. The close association with copper sulphides suggests the germanium sulphides will in part be recovered in the copper concentrate during flotation without special or additional processing.

Tony Giardini, President and CEO of Trilogy, commented “We are excited about our ongoing collaboration with the USGS and the Colorado School of Mines. Germanium is an important metal with numerous applications, particularly in the manufacture of semiconductor chips, fiber-optic systems, and high efficiency solar cells. Prices for the high-value metal have steadily climbed to approximately $2,750 per kilogram, a 35% increase from January 2020. We believe this trend will continue due to China’s recent export curb. It is imperative that other sources of germanium are developed. The most significant Western source is the Red Dog Mine in Alaska, operated by Teck Resources Limited in partnership with the land owner, NANA, which is approximately 320 km from the Ambler Mining District.”

Richard Gosse, VP Exploration of Trilogy, said “I would like to thank Alexander Jones for the research he did as part of his MSc thesis at the Colorado School of Mines on the distribution of germanium at the South Reef deposit, as well as his supervisor, Dr. Katharina Pfaff, Manager of the School’s Mineral and Material Characterization Facility, and Dr. Garth Graham of the USGS for their oversight and assistance in the collection and subsequent studies. The high standard of their analytical work has highlighted the importance of germanium at Bornite and we look forward to contributing to their new project to better understand the availability of critical mineral resources in the US.”

Germanium at Bornite

The under-reporting of germanium using a standard analytical method was recognized by the Company in 2011. At that time, 50 mostly continuous core samples ranging from 0.65 to 3.34 meters were selected from four drill holes. Germanium values ranged from <1 to 83 ppm compared to a maximum value of 1.15 ppm using a standard analytical method. The best composite result obtained was 17.56 meters averaging 30 ppm germanium with 12.48% copper (see Table 2), part of a 176-meter drill intercept grading 4.01% copper in hole RC11-0187. Prior to this work, only six samples from Bornite are known to have been analyzed for germanium using sample preparation methods specifically for germanium. Including the samples used in the Jones thesis, it appears only 140 samples have been correctly analyzed for germanium in the 70+ years since the first hole was drilled at Bornite.

Work has now started to accurately determine the amount and distribution of germanium at Bornite. Samples collected by Trilogy from Kennecott’s pile of mineralization that was excavated during shaft sinking in the 1960s were recently analyzed at an ALS laboratory in Australia using an analytical method specialized to prevent the loss of the volatile germanium compound. The results confirm the loss of germanium using the standard four acid digest. In addition, Ambler Metals will soon begin re-analyzing 14 composite samples and their resulting concentrates obtained from metallurgical test work conducted in 2019 and 2021.

Finally, Ambler Metals has recently accepted a proposal from the Center to Advance the Science of Exploration to Reclamation in Mining (“CASERM”) at the School with leveraged USGS funding to contribute samples from Bornite to further investigate the occurrence, distribution, and sequestration of critical elements, including germanium, using a suite of micro-analytical methods such as SEM- and XRF-based techniques, electron probe micro analysis, and LA-ICP-MS. Objectives of the study include compiling a comprehensive whole-rock 60+ geochemical dataset of select samples from the Bornite deposit that complement the existing dataset from South Reef related to the MSc study. Additional sampling of mineralized core for the study is in progress.

Germanium

Various modern technologies, including infra-red systems used in thermal imaging applications such as night-vision goggles, as well as fiber optics, semiconductors, and solar panels, use germanium. About 130 tonnes of germanium are produced globally each year, up from 50-70 tonnes twenty years ago, primarily from zinc residues and fly ash (waste from the burning of coal), with China producing between 60-80%. Supply and price are largely determined by recovery processes, geopolitical and legislative factors, and environmental regulations.

Estimates on the future demand for germanium vary widely and are largely based on different solar energy scenarios. Germanium is an essential component of solar photovoltaic cells that use amorphous silicon-germanium thin film technology. Future technologies that could also strongly affect demand are fiber optics and SiGe semiconductors used in 5G telecom and related infrastructure. For more information on the demand and uses of germanium, see the paper by Madhav Patel and Athanasios Karamalidis1.

Copper and Cobalt

Copper mineralization at Bornite comprises chalcopyrite, bornite, and chalcocite as stringers, veinlets, and breccia fillings in hydrothermally altered dolostone within a sequence of alternating carbonates (limestones and dolostones) and calcareous phyllite. As with the other world-class carbonate-hosted copper deposits, such as at Kipushi (DR Congo) and Tsumeb (Namibia), Bornite shows early pyrite-dolomite alteration followed by copper-dominant sulphide mineralization with associated cobalt, germanium, silver, and zinc.

Studies of cobalt mineralization at Bornite indicate that most of the cobalt occurs as cobaltiferous pyrite both within and enveloping the deposit. Cobalt is also present as two cobalt-bearing sulphides, carrollite and cobaltite, that are associated with the copper mineralization. The Bornite Technical Report (as defined below) on the Mineral Resource Update of the Bornite project includes representative drill hole intersections with cobalt grades showing drill holes within South Reef containing higher grades than drill holes in-pit.

Critical Minerals and Alaska

Critical minerals such as copper, cobalt and germanium play an essential role in powering modern technologies, from renewable energy systems and electric vehicles to advanced electronics and national defense. Trilogy’s management is confident that high-grade Alaskan mineral deposits such as Bornite can play an important role in securing a reliable supply of these materials, which are essential for the United States’ economic competitiveness and national security.

Copper, cobalt and germanium are included in the US Critical Materials list, which informs eligibility for tax credits for suppliers under the Inflation Reduction Act.

Table 1. Mineral Resources for the Bornite Deposit.

|

Class |

Type/Area |

Cut-off |

Tonnes |

Average Copper Grade (%) |

Contained Copper (Mlb) |

|

Inferred |

In-Pit |

0.5 |

170.4 |

1.15 |

4,303 |

|

|

Outside-Pit |

1.79 |

22.0 |

3.48 |

1,690 |

|

|

Outside-Pit |

1.79 |

10.4 |

2.28 |

521 |

|

Total Inferred (100%) |

|

|

202.7 |

1.46 |

6,514 |

|

Total Inferred (50% Attributable Interest) |

101.3 |

3,257 |

Notes:

- The effective date of the mineral resource is January 26, 2023. The QP for the mineral resource is an employee of Wood Canada Limited.

- Mineral Resources are prepared in accordance with CIM Definition Standards (2014) and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (CIM, 2019).

- Mineral resources are constrained by: an open pit shell at a cut-off grade of 0.5% Cu, with an average pit slope of 43 degrees; and underground mining shapes with a cut-off grade of 1.79% Cu. The cut-off grades include the considerations of a $4.05/lb Cu price, process recovery of 87.2%, open pit mining costs of $3.21/t mined, underground mining cost of $73.62/t mined, process cost of $19.14/t processed, G&A cost of $4.14/t processed, treatment, refining, sales cost of $0.73/lb Cu in concentrate, road use cost of $8.04/t processed, 2% NSR royalty.

- Figures may not sum due to rounding.

- See technical report titled “NI 43-101 Technical Report on the Mineral Resource Update of the Bornite Project, Northwest Alaska, USA” with an effective date of January 26, 2023 and a release date of February 14, 2023 (the “Bornite Technical Report”).

Table 2. Significant composite intercepts of germanium from a 50-sample subset of reanalyzed 2011 drill core using standard and germanium-specific analytical methods. Composites were selected based on an approximate 10 ppm cut-off.

|

Hole |

From (m) |

To (m) |

Width (m) |

Copper Grade (%) |

Germanium (ppm) |

Associated Mineralogy |

|

RC11-0183 |

323.74 |

330.49 |

6.75 |

24.47 |

16 |

bn-cp-py |

|

RC11-0185 |

173.74 |

178.26 |

4.52 |

7.96 |

9 |

bn-cp-py |

|

RC11-0187 |

458.79 |

476.35 |

17.56 |

12.48 |

30 |

bn-cc-cp-py |

|

RC11-0194 |

756.53 |

762.13 |

5.60 |

9.80 |

8 |

bn-cc-cp-py |

Table 3. 2011 drill hole locations, depths and orientations.

|

Hole |

Easting |

Northing |

Elevation |

Depth |

Azimuth |

Dip |

|

RC11-0183 |

589401.6 |

7440451 |

198.307 |

359.36 |

112.9 |

-58.2 |

|

RC11-0185 |

589129.7 |

7439619 |

255.592 |

350.52 |

86.3 |

-52.4 |

|

RC11-0187 |

590273.5 |

7440008 |

306.097 |

714.75 |

122.4 |

-85.5 |

|

RC11-0194 |

590478.7 |

7440196 |

265.651 |

782.42 |

1.3 |

-70.4 |

Figure 1. Location of Bornite, Arctic and the Upper Kobuk Mineral Projects area.

Figure 2. Bornite deposit with South Reef, Ruby Zone and resource pit (Upper and Lower Reefs) showing cobalt grades in drill holes.

Figure 3. Renierite (germanium sulphide) closely associated with copper sulphides visible under reflected light for two samples from 490.86 meters (A) and 472.6 meters (B) from hole RC11-0187 (from thesis by A. Jones).

1 M. Patel & A. Karamalidis, Germanium: A review of its US demand, uses, resources, chemistry and separation technologies; in Separation and Purification Technology, Elsevier, 2021.

QA/QC Program

The drilling program, sampling and assaying protocol, and data verification for germanium completed during 2011 were managed by qualified persons (QPs) employed by NovaCopper Inc. The diamond drill holes were completed using HQ or NQ diameter core. Drill core was cut lengthwise into halves using a diamond saw; one-half was used for the assay sample and the other half retained in core boxes and archived at site. Samples were collected through mineralized zones using a 0.3 m minimum length and 3.1 m maximum length; median sample length is 2.6 m.

Each core sample was placed into a bag with a numbered tag, and quality control samples were inserted between core samples using the same numbering sequence. The samples were grouped into batches for shipping and laboratory submissions. Each batch of 20 samples contains one certified reference material (CRM), one blank (BLK), and one crushed duplicate (DUP). Blank samples are commercial landscape marble. Duplicate samples were prepared at the sample preparation facility by taking a second split from the entire crushed sample. Chain of custody records were maintained for sample shipments and the custody was transferred upon delivery from NovaCopper expeditor to the laboratory.

Samples were shipped to ALS Minerals laboratory in Fairbanks, Alaska, USA, for sample submission. ALS Minerals Fairbanks is a satellite sample preparation facility accredited under ALS Minerals. The ALS Minerals Fairbanks shipped the samples to ALS Minerals in Reno, Nevada, USA, for sample preparation and analysis. ALS Minerals is an independent laboratory certified under ISO 9001:2008 and accredited under ISO/IEC 17025:2005. ALS Minerals includes its own internal quality control samples comprising certified reference materials, blanks, and pulp duplicates.

Drill core samples were weighed, dried, coarsely crushed to 70% passing 6 mm, finely crushed to 70% passing 2 mm, riffle split to 250 g subsamples, and pulverized to 85% passing 75 μm. Gold analyses were completed using a 30 g lead fire assay and AAS finish (Au-AA23). Multi-element analyses for 48 elements were completed using a geochemical four acid digestion and ICP-ES/MS finish (ME-MS61m). Over-range assays for Ag, Cu, Zn, and S were completed using an ore grade four-acid digestion and ICP-ES finish (ME-OG62). Additional analyses were completed for Ba and Hg.

Au, Ag, Cu, Pb, and Zn assays for QC samples were reviewed to ensure that CRMs are within tolerance limits specified on supplier certificates; BLKs are below acceptable thresholds; and DUPs display statistical patterns normally expected for sample types, methods, and elements.

Samples submitted for germanium check analyses were analyzed at ALS Minerals by a three acid digestion (Ge-MS66), which comprises nitric-hydrofluoric-orthophosphoric acids specifically set up to avoid volatilization of germanium chloride that occurs with a conventional four acid digestion that comprises nitric-perchloric-hydrofluoric-hydrochloric acids. Although external germanium CRMs were not included with the check samples, higher germanium values are more in-line with expectations based on mineralogy.

Qualified Person

Richard Gosse, P.Geo., Vice President Exploration for Trilogy Metals Inc., is a Qualified Person as defined by National Instrument 43-101. Mr. Gosse has reviewed the technical information in this news release and approves the disclosure contained herein.

About Trilogy Metals

Trilogy Metals Inc. is a metal exploration and development company which holds a 50 percent interest in Ambler Metals LLC, which has a 100 percent interest in the Upper Kobuk Mineral Projects in northwestern Alaska. On December 19, 2019, South32, a globally diversified mining and metals company, exercised its option to form a 50/50 joint venture with Trilogy. The UKMP is located within the Ambler Mining District which is one of the richest and most-prospective known copper-dominant districts in the world. It hosts world-class polymetallic volcanogenic massive sulphide (“VMS”) deposits that contain copper, zinc, lead, gold and silver, and carbonate replacement deposits which have been found to host high-grade copper and cobalt mineralization. Exploration efforts have been focused on two deposits in the Ambler Mining District – the Arctic VMS deposit and the Bornite carbonate replacement deposit. Both deposits are located within a land package that spans approximately 190,929 hectares. Ambler Metals has an agreement with NANA Regional Corporation, Inc., an Alaska Native Corporation that provides a framework for the exploration and potential development of the Ambler Mining District in cooperation with local communities. Trilogy’s vision is to develop the Ambler Mining District into a premier North American copper producer while protecting and respecting subsistence livelihoods.

Company Contacts

|

Tony Giardini |

Elaine Sanders |

Phone: 604-638-8088

# # #

Cautionary Note Regarding Forward-Looking Statements

This press release includes certain "forward-looking information” and "forward-looking statements” (collectively "forward-looking statements”) within the meaning of applicable Canadian and United States securities legislation including the United States Private Securities Litigation Reform Act of 1995. All statements, other than statements of historical fact, included herein, including, without limitation, perceived merit of properties, outcomes of studies and testwork, the amount and distribution of germanium at Bornite, the role and demand of critical minerals such as copper, cobalt, germanium and deposits such as Bornite, and the Company’s plans to conduct further studies, provide further updates and the timing thereof are forward-looking statements. Forward-looking statements are frequently, but not always, identified by words such as "expects”, "anticipates”, "believes”, "intends”, "estimates”, "potential”, "possible”, and similar expressions, or statements that events, conditions, or results "will”, "may”, "could”, or "should” occur or be achieved. Forward-looking statements involve various risks and uncertainties. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from the Company's expectations include the uncertainties involving our ability to conserve cash and to raise capital at terms favorable to the Company, or at all and other risks and uncertainties disclosed in the Company’s Annual Report on Form 10-K for the year ended November 30, 2022 filed with Canadian securities regulatory authorities and with the United States Securities and Exchange Commission and in other Company reports and documents filed with applicable securities regulatory authorities from time to time. The Company's forward-looking statements reflect the beliefs, opinions and projections on the date the statements are made. The Company assumes no obligation to update the forward-looking statements or beliefs, opinions, projections, or other factors, should they change, except as required by law.